Advanced Engineering and Sustainability in Furlerboom Manufacturing

Furlerboom has conducted Finite Element Method (FEM) analysis, as well as torsion and stress tests, on all models, including carbon and fiberglass versions.

This is to ensure that the strength of the bottom is correct without compromising the weight of the Furlerboom or safety.

The Furlerboom is molded by:

-

All Comaxel's energy used for the production/casting of the Furlerbooms is sourced from 100% renewable energy.

-

Comaxel Sp. z o. o. is certified by Bureau Vertitas and has an integrated management system that covers both quality, the environment and the working environment.

-

All materials and auxiliary materials for production are produced in Europe.

-

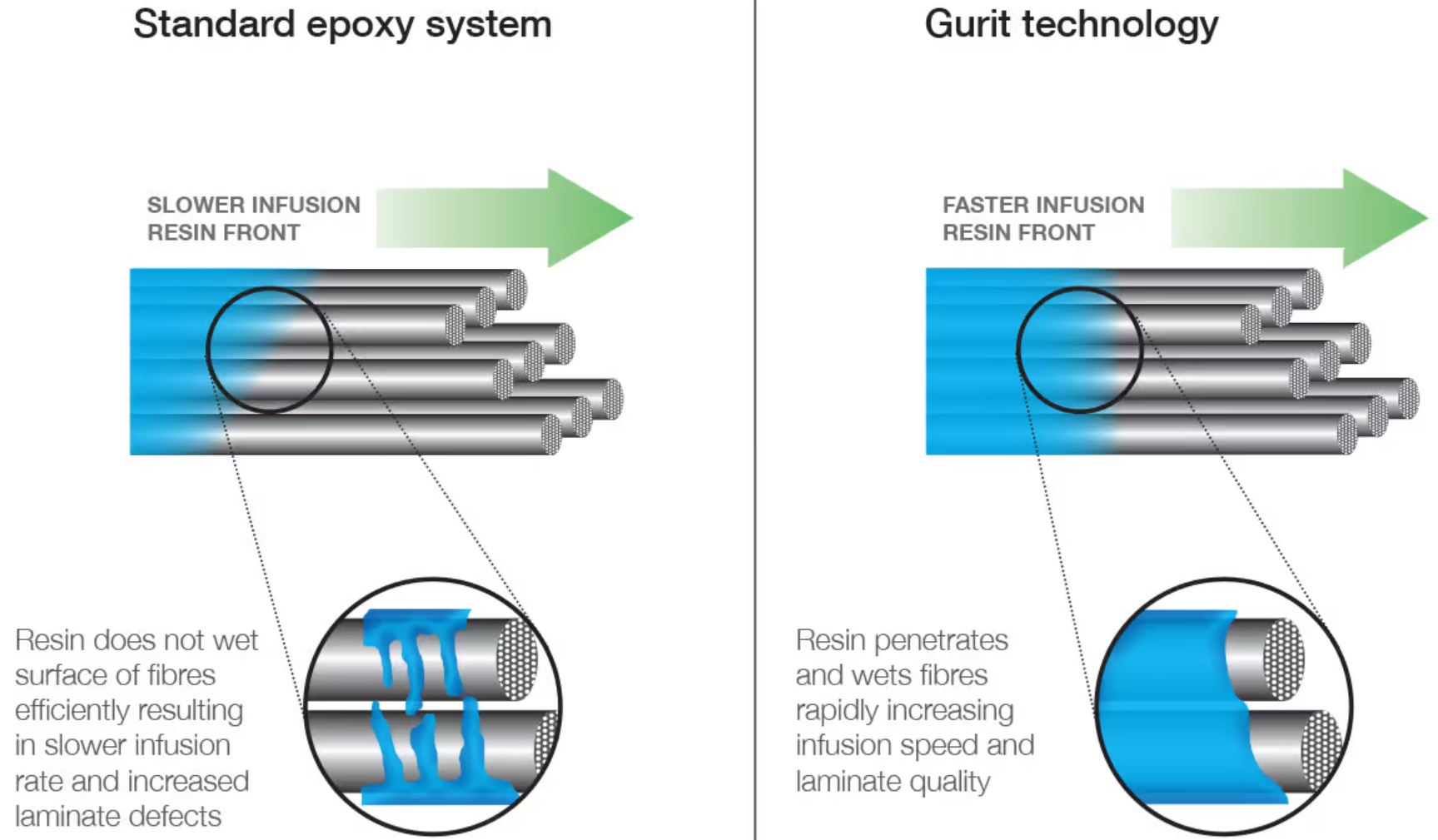

Produced with the new “Low toxicity “ Epoxy “PRIME” containing 37-40% plant-based oil and Lloyd’s certified by their material supplier GURIT.

o Mixed viscosity remains lower for longer duration.

o Faster through-cure, avoiding a low-strength “ Sugary” phase.

o Improved exotherm control.

Molding process

-

Backed for up to 8 hours with 60°C to ensure the best possible curing process. The information/documentation regarding to the baking process is stored by Comaxel Sp.z o.o. for 5 years once the Furlerboom has been taken out of the casting mold.

-

A transillumination test will be performed to indicate any possible dry stops or faults in the newly molded Furlerboom.